Novel technology for the lime-free flotation separation of Pb-Zn-S with better metallurgical performance and simplified waste water treatment process.

INTRODUCTION

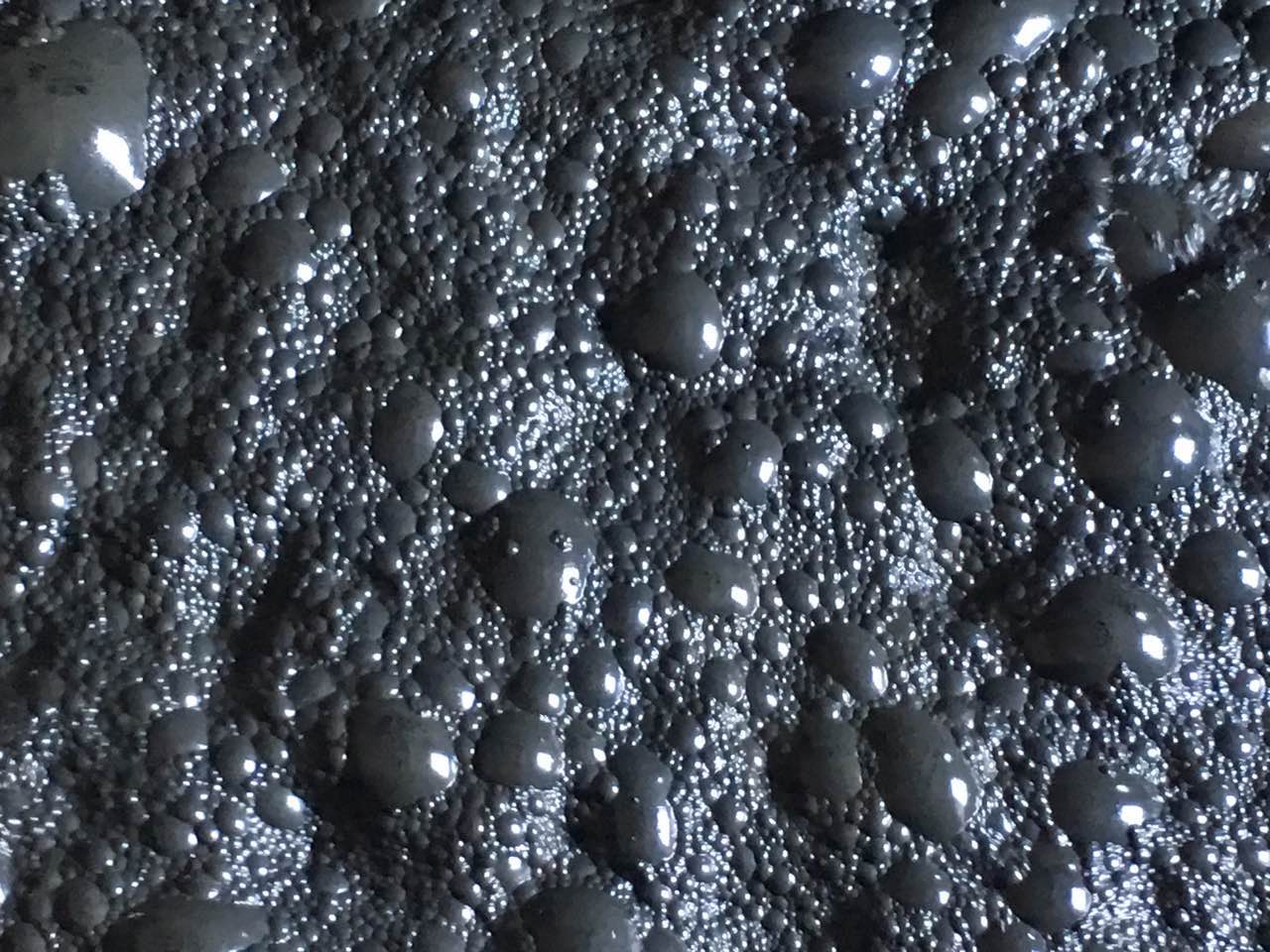

Lead-zinc sulphide ore contains lead sulphide (galena), and zinc sulphide (sphalerite). For Lead-zinc sulphide ore, the most widely used method is that of two stage selective flotation, where the zinc and iron minerals are depressed, allowing the galena to float, followed by the activation of the zinc minerals in the lead tailings to allow a zinc float.

In the conventional process for the separation of Zn-S, sphalerite is activated by CuSO4, then floated by Butyl xanthate, while huge amount of lime is required to depress sulphide, which leads to the following problems in the production:

Pipe blocking due to the solubility of lime slurry, difficulty for the treatment of waste water as the amount of acid is difficult to control to neutralize the water, higher consumption of lime (>5kg/t) requires more staff on site and lower recovery of precious metal (Ag/Au) under higher alkalinity.

The client has been searching for the solution for a long time, as the preparation of lime slurry requires 2-3 staff each shift, while the biggest problem is the treatment of waste water, the addition of acid to neutralize the water is not stable, which fluctuates up and down, also the concentration of heavy metals are higher under alkalinity condition .

DEVELOPMENT

Initially, the flowsheet in the plant is as following: lead flotation followed by mixed flotation of Zn-S, then Zn-S flotation separation under higher alkalinity (pH 10-12). Numerous tests were carried out to synthesize new collector for sphalerite and selective depressant for pyrite instead of lime, also the flowsheet has been optimized and modified to lead flotation-Zinc flotation-pyrite flotation instead of mixed Zn-S flotation. Better metallurgical performance had been obtained and the process for waste water treatment has been completely simplified.

(1) Better metallurgical performance comparing with traditional process;

(2) No more staff needed for the preparation of lime slurry;

(3) Simplify even no waste water needs to be treated;

(4) Huge direct revenue and environmental benefits;

The innovative technology and reagents developed in this project is being applied in a couple of Pb-Zn-S mining plants in China, which could be used in other similar mining plants around the world, as the metallurgical performance could be improved with less operating cost, as well as simplified waste water treatment process.